TEL: 02392 382386

Portable Appliance Testing

The ELECTRICITY AT WORK REGULATIONS 1989 for the safe use of electricity and electrical appliances in the workplace and public places, came into force in 1990 (these regulations are statutory, and therefore the law).

The ELECTRICITY AT WORK REGULATIONS 1989 for the safe use of electricity and electrical appliances in the workplace and public places, came into force in 1990 (these regulations are statutory, and therefore the law).

They place a legal onus on every employer or persons responsible (known as the Duty Holder) to ensure that all Electrical Appliances are safely maintained. The guidelines for the frequency of testing are promulgated by the Institute of Electrical Engineers (IEE) and the HSE.

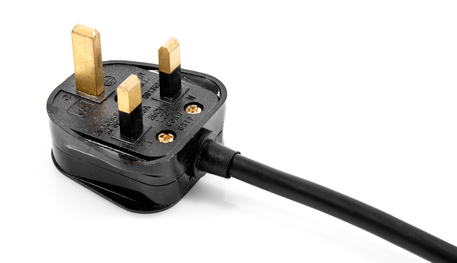

New equipment may not be manufactured to British Standards and therefore still requires testing and inspecting. Any equipment used on the premises (whether personal or not) should be tested, equipment not in use should be marked DO NOT USE BEFORE SAFETY ELECTRICAL TEST and the fuses removed. Faulty equipment should be repaired or disposed of (not put away in the cupboard).

IEE guidance and addendums specify that IEC leads (independent electrical leads) should be tested and labelled separately.

Glossary:

| Class 1 | Equipment with an Earth Lead |

| Class 2 | Equipment without an Earth Lead (must be double insulated) |

| RWSI | Rewire to secure insulation (typically, either not secured under the collar at the plug, or the phase and neutral lead showing outside the plug, and therefore, not double insulated). |

| XTN | Extension Lead |

| NA | Not applicable (typically, on class 2 equipment, there is not earth lead, and therefore no Earth Bond reading.) |

| IEC | International Electrical Cord (like a kettle or PC lead). |

| PSU | Power Supply Unit. |

NOTE:

1. Extension leads over 25 mtrs, should only be used with an in line RCD.

2. This test is for Portable Appliances only, and does not test socket outlets. Class 1 equipment relies on the Earth connection in a socket outlet for safety. Fixed Electrics should be tested regularly i.a.w. BS 7671: 2008 recommendations.

3. All ONE, TWO and THREE way adaptors and extension leads should be fused.